Ultimate efficiency engine: FVV Researchers significantly increase fuel efficiency in the real world of road transport

Four research institutes in Aachen, Braunschweig, Darmstadt and Stuttgart have investigated on behalf of the Research Association for Internal Combustion Engines (FVV) how close we can come to the ultimate system efficiency of combustion engines in hybrid powertrains. Their conclusion: if available prime mover SI engine technologies are optimally matched to each other, more than 40 percent of the energy bound in the fuel can be used in real road transport. Synthetic fuels (e-fuels) can lead to even higher efficiency due to their better combustion properties.

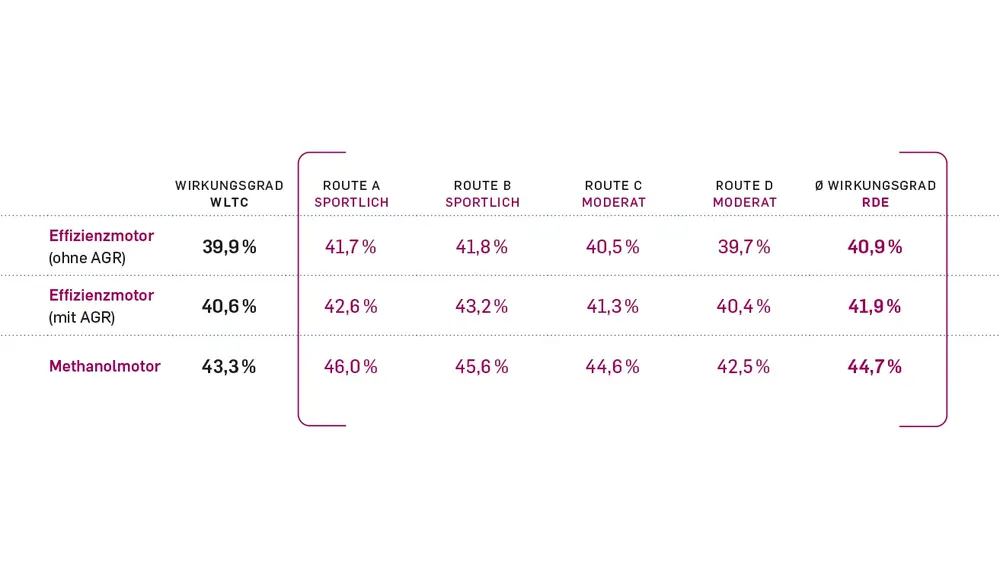

ICE2025+: the ultimate system efficiency // Theory is one thing, but practical application is another altogether. Over the last two years, four research institutes have investigated on behalf of FVV how close we can come to the thermodynamic optimum in real driving operation, and what this means for the efficiency of a vehicle. The key requirement here was that the researchers were only to consider technologies that would be ready for series production over the coming years and thus help adhere to the CO2 limits applicable from 2030. In addition, their objective was not to achieve a single peak value in a certain point on a characteristic map. »Our goal was to reach an average efficiency of more than 40 % in a realistic driving cycle such as the Worldwide Harmonized Light-Duty Vehicles Test Cycle (WLTC),« explains Christian Beidl. In the ›ICE2025+‹ project, the head of the Institute for Internal Combustion Engines and Powertrain Systems at the Technical University of Darmstadt and his colleagues Stefan Pischinger from Aachen, Peter Eilts from Braunschweig and Michael Bargende from Stuttgart investigated the extent to which the efficiency of spark-ignition passenger car engines can be improved in hybridised powertrains.

- »ICE2025+: Ultimate System Efficiency [1307]

Limits to increasing the efficiency of spark-ignited engines in hybrid powertrains«

- PROJECT FUNDING

€ 1.2 million // FVV

- PLANNING GROUP

PG2 ›Combustion SI‹

- PROJECT COORDINATORS

Arndt Döhler (Opel Automobile)

Dr André Casal Kulzer (Porsche)

Institute of Automotive Engineering (IFS), Chair of Automotive Powertrains, University of Stuttgart

Head of Research: Prof Dr Michael Bargende

Institute for Internal Combustion Engines and Powertrain Systems (vkm), Technische Universität Darmstadt

Head of Research: Prof Dr Christian Beidl

Institute for Combustion Engines (vka), RWTH Aachen University

Head of Research: Prof Dr Stefan Pischinger

Institute for Internal Combustion Engines (ivb), Technische Universität Braunschweig

Head of Research: Prof Dr Peter Eilts

The technologies that can be used to raise the efficiency of a piston engine are already known: variable compression and flexible valve control times, exhaust gas recirculation, control of the charge movement, pre-chamber ignition, water injection and long-stroke engine design. Hybridisation can also contribute to lower fuel consumption, as the vehicle is driven electrically in very low load ranges in which the spark-ignition engine has poor efficiency due to its functional principle. The framework conditions of the ›ICE2025+‹ project specify that only electrical energy generated on board may be used.

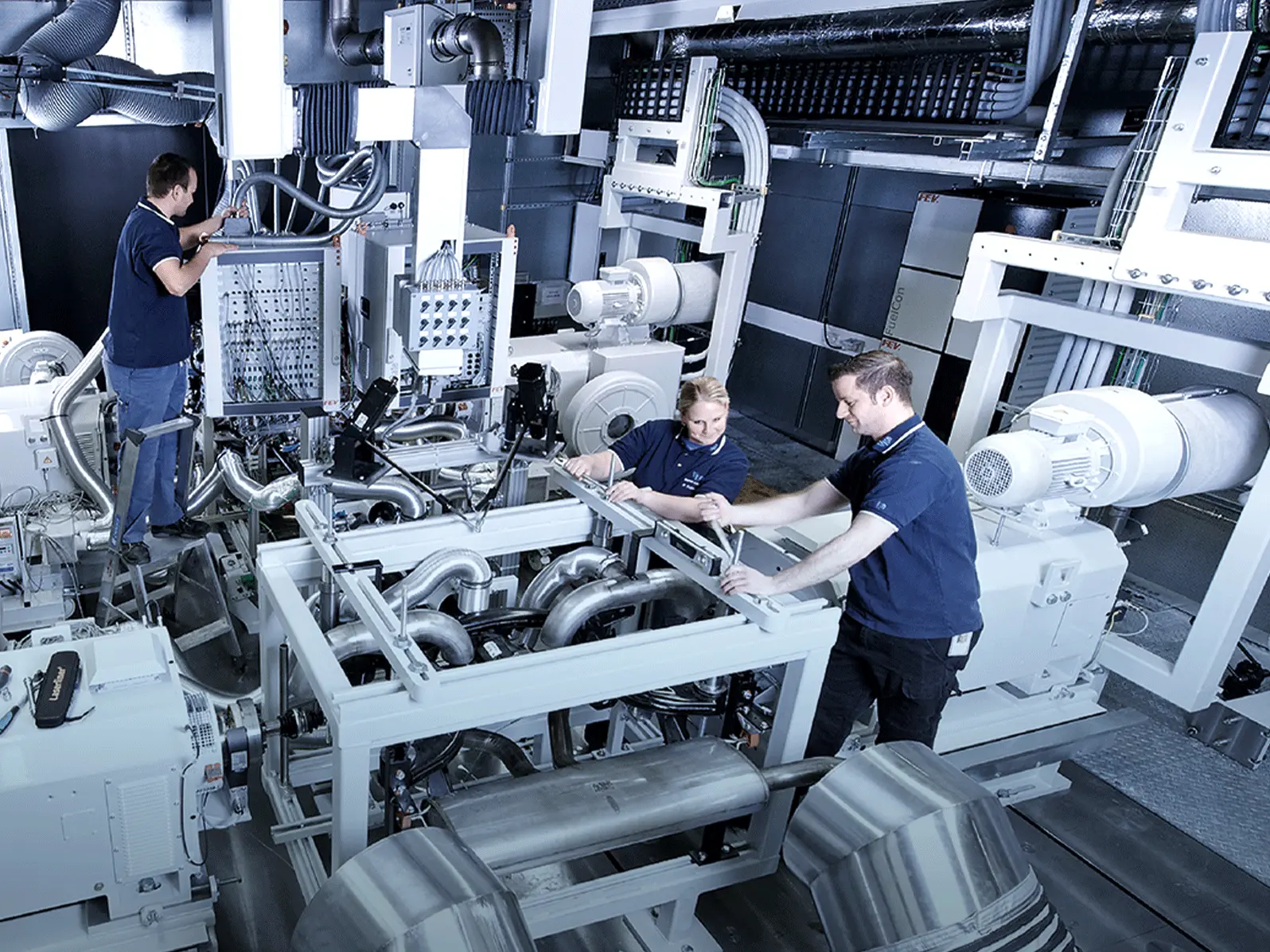

One problem remains, however: consumption is only actually optimised when all the technologies used work together. Simply adding individual measures is not an option, as in extreme cases technologies can neutralise each other if the operating strategy is not adjusted. »That is why we have taken a systematic approach from the beginning,« says Beidl. To this end, it was not only the technologies that had to work together perfectly, but also the institutes. Consumption measurements for individual technology packages were initially performed on a single-cylinder research engine at the Institute for Internal Combustion Engines (ivb) at TU Braunschweig. These were then used at the Institute of Automotive Engineering (IFS) at the University of Stuttgart to create an engine simulation model and, on the basis of this, a characteristic map for a complete virtual engine. Next, the researchers in Darmstadt used this characteristic map to simulate complete vehicles and determine how much of the chemical energy from the fuel actually reaches the tarmac. During the process, they examined both different vehicle classes and a range of hybrid configurations. In further experiments at the Institute for Combustion Engines (VKA) at RWTH Aachen University, the normal petrol fuel was then replaced by alternative energy carriers. »One of the reasons we chose methanol was because it has outstanding combustion properties and is among the renewable liquid fuels that is most efficient to manufacture,« says Stefan Pischinger, head of the institute at RWTH Aachen University. The data generated during this stage was also used for the engine simulation at the University of Stuttgart, before the researchers in Darmstadt calculated the real driving efficiency on the basis of the findings.

Two years after the project start and just before completion, it was already evident that the 40 % target for a mid-range vehicle (C-segment) is achievable if it is run with normal fuel and equipped with a P1 or P2 hybrid powertrain. »These values are achieved not only in the WLTC test bench cycle, but also in various RDE cycles,« comments Beidl. RDE stands for ›real driving emissions‹ and replicates driving in road transport. When the researchers in Aachen and Stuttgart replaced the standard fuel with methanol, the results were even better: the powertrain in the C-segment vehicle with transmission-integrated hybrid powertrain achieved an efficiency of 43.4 % in the standard cycle, and an average of 42.7 % in simulated road transport. »This is mainly due to the higher combustion speed of methanol,« says Michael Bargende from the University of Stuttgart.

If the technologies researched in ›ICE2025+‹ entered series production, we would have an extremely efficient petrol engine. Due to its functional principle, it cannot quite reach the efficiency of a diesel engine as long as it is run with a stoichiometric air-fuel ratio (lambda = 1). However, the method of exhaust gas purification via three-way catalytic converter proven in spark-ignition engines still works, and the significantly more complex SCR technology seen in diesel engines is not needed. The additional potential of lean-burn operation was also investigated, albeit also with technologies oriented towards a series launch. »When the methanol engine is run with excess air, the consumption level is even better than that of a diesel car,« states Bargende. »An efficiency value of more than 40 % is achieved in a large part of the engine characteristic map, and even 46.9 % at its peak.« Compared to a current spark-ignition engine that corresponds to the state-of-the-art in every way, this gives a CO2 reduction of up to 25 %.

»Exactly that was our goal,« stresses Beidl. »We wanted to achieve a significant reduction in consumption across the entire characteristic map, not just a single peak value at a certain operation point.« The specialist is convinced that, »even if individual technologies such as variable compression do not make it into series production, the efficiency of the spark-ignition engine can still be improved considerably.«